MARTIN SPLICER IMPROVES EFFICIENCY OF ABG LINE TO BOOST BUSINESS

Posted: May 21, 2015

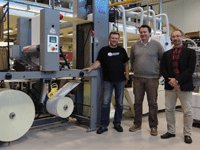

(Left to right) Thor Jorgen Kasbo and Tom Bulow-Kristiansen of NorStamp with Joakim Marcusson of Convertec, who supplied the Martin splicer.

"The installation of a Martin Automatic splicer has made our prices more competitive by cutting waste and improving accuracy and quality," stated Tom Bulow-Kristiansen, Sales Manager of the Labels Division at Norwegian converter NorStamp. The Martin splicer, an MBSC model, is fitted to an ABG Omega ATR label finishing line at the company's plant in Stokke, about 100 kms south of the country's capital, Oslo. According to Bulow-Kristiansen: "Since we fitted the Martin to the ABG equipment, our blank label throughput has grown from 20 million to 48 million labels per year because we can run non-stop with higher production speeds. And, the quality has improved too because the Martin has given us better tension control on the web."

The ABG equipment offers label-finishing techniques such as die cutting, and runs mainly reel-to-reel into an Omega ATR (Automatic Turret Rewind) at speeds of around 185 metres/minute. "The Martin allows us to run 3000 metre rolls continuously, which equates to about 15,000 to 18,000 metres a day. This has more than doubled our output. Less downtime, less waste, greater accuracy, and a consistent quality splice all make for better margins - the Martin has transformed our production here," he added.

Speaking for Convertec, Scandinavia's independent converting technology specialists, Joakim Marcusson commented: "The MBSC is an ideal machine for NorStamp's type of operation. The 'C' stands for 'Compact', because the unit has a tiny footprint of about two metres, but it is otherwise a fully functioning splicer that is based on the very successful MBS series that Martin Automatic has installed around the world. The difference it has made to the performance of the otherwise excellent ABG line here is outstanding, and offers it a relatively low cost route to higher performance and increased efficiency for any company running narrow web products."

NorStamp, as its name suggests, started life manufacturing pre-inked rubber stamps, and still holds the major share of the Norwegian market in this field. But demand has flat-lined, and the company has moved more recently into packaging, labels, and sign work. The company is keen to grow its IML business, and claims that where most suppliers see 50,000 tubs as the minimum viable quantity, NorStamp can profitably go down to 10,000. Labels are also seen as a major growth opportunity, with Etipol rotary letterpress technology, and an HP-Indigo WS4500 providing in-house digital printing, where the labels are finished on an ABG Digicon converting line that offers varnishing and laminating offline. Flexo printing is currently being outsourced.

"We use the Etipol for jobs up to about 40,000 labels, and the HP for shorter run work of typically 5000 - 6000 labels. But it's the blank label side that is showing the biggest growth, with the ABG/Martin line handling runs of any length and being kept permanently busy. This indicates a growth in the logistics and delivery trade, and in this area we are working closely with the Norwegian fishing industry," commented Bulow-Kristiansen.

With encouragement and funds to invest from its parent company, NorStamp is optimistic about its future, and with a wider portfolio of products to offer, the company looks certain to build on its almost 40 year history.